Joint Research Activity

Grounded on its TOP partners background and in Sol2H2O objectives towards the WIDENING enhancement, the Joint Research Activity (JRA) aims at the design and construction, at the Widening RI, of an innovative Solar-driven WP&WT pilot. An original hybrid scheme powered by solar energy is here proposed to ensure the sustainability of the overall process, leading to the maximization of freshwater and approaching zero liquid discharge (ZLD), as no brine will be rejected.

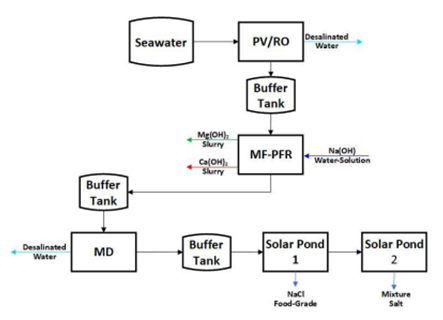

This pilot aims at beyond SoA recovery rates: >80% (SoA ca. 50%). The treatment chain, depicted in Figure 1, consists of: (i) Photo-Voltaic (PV) panel and Reverse Osmosis (RO), (ii) Multiple Feed Plug Flow Reactor (MF-PFR), (iii) Membrane Distillation (MD) and (iv) two solar ponds. Seawater is sent to the RO unit powered by the electrical energy produced by PV panels, and produces two streams: a permeate (high-grade quality water for industrial and drinkable purpose) and a retentate (i.e. the brine) enriched in all ions present in seawater. The retentate is sent to the MF-PFR unit for the selective recovery of magnesium and for the removal of calcium in the form of hydroxides. The recovery/removal of magnesium and calcium is carried out by a fractionated chemical precipitation adding an alkaline reactant, such as sodium hydroxide water solution. The double step of selective recovery is performed by accurate control of the reaction pH, since a pH value of 10.4 is required for the complete precipitation of magnesium hydroxide with high purity and a pH higher than 13 is required for the complete removal of calcium. The recovery of magnesium hydroxide with high purity is considered a product at the highest added value contributing to making the treatment chain more profitable.

Meanwhile, the removal of calcium is crucial in order to avoid precipitation of salts, such as calcium sulfate, in the MD unit.The capacity of the MF-PFR pilot unit is about 1 m3/day of brine treated. Afterwards, the effluent produced by the MF-PFR is sent to the MD unit, which produces two different streams, one is a distillate and the other one is a retentate, whose concentration can reach about 250,000 ppm. This high concentrate brine exiting MD is sent in a first solar pond (Solar Pond 1) producing NaCl at food grade (purity higher than 97%) and a remaining brine depleted in NaCl. The remaining brine is sent to the last pond (Solar Pond 2) for complete evaporation of water precipitating a mixture of chloride and sulfate salts, which can be used for deicing purposes. Thanks to the use of the two solar basins, the whole treatment chain meets the Zero Liquid Discharge concept because no effluents are produced and then released into the environment. Furthermore, and building on the existing solar photocatalysis reactor at the Widening RI, further enhancement on open concepts for photo-reactors will be tested. The JRA serves as the “test bed” for the implementation of the support measures envisaged in Sol2H2O.

Tasks

Solar-driven Water production and zero-liquid discharge solutions

Led by ITC, this task aims at developing the ground know-how for the ensuing development of cutting-edge research in the fields of solar-driven water production and zero-liquid discharge to achieve a sustainable integrated seawater treatment chain for the production of fresh water and raw materials. By means of solar-driven heat and power supply as energy source to water production, has technological focus on: – Photovoltaic powered – Reverse Osmosis (PV-RO) desalination; – Vacuum-enhanced air-gap Membrane Distillation for fresh water production from brines and its coupling with solar thermal energy under dynamic conditions; – Brine treatment processes for raw materials recovery and Zero Liquid Discharge (e.g., reactive crystallization for the recovery of magnesium and calcium hydroxides, and solar-driven evaporation for sodium chloride production); and encompasses a technical-economic assessment of these technological approaches, reported in D2.1. This task bases the development of 1 PhD Thesis foreseen in the PhD Facility sought.

Solar driven wastewater treatment

Led by CIEMAT, this task will be focused on the design and construction of new concepts of solar photoreactors for different applications, industrial wastewater and urban wastewater and disinfection for reusing purposes (mainly in agriculture activities). The two main research lines that will be tackled in coordination with the widening partner are: - Improvement and optimization of photoreactors, like the absorber tube diameter of the CPC or the agitation mechanism in raceway pond reactors (RPR), to better fit the AOP to be applied, the raw characteristics of the wastewater to be treated and the water quality required depending on final reuse purposes; – combination with PV systems for renewable energy supply to the electrical parts of the solar photoreactors. This task will contribute to part of 1 PhD Thesis.

Distributed Facility

Aiming at the ensuing development of remote R&D activities and services in the Widening RI, this task entails the design, installation and commissioning of a data server for experimental data monitoring, processing and remote access. Encompassing the monitoring of the different parameters under monitoring in the different assets in the facility, this server system will ensure data processing and backup, enforcing FAIR (findable, accessible, interoperable and reusable) research data management, providing proper data security (including data recovery), thus implemented within a Data Management Plan. This will allow full control over the infrastructure data (in the integrated asset management policy of the IT Division of UEvora), its sharing interfaces, while minimizing curation and storage/preservation costs. For communication with this server, all existing assets will be adapted in order to guarantee the safe and reliable transmission of data on their status, alarms, operation and performance, etc. The development of this task is reported in Deliverable D2.2 (design and commissioning).